Manufacturing: TECVAL, Colombia

Support: TECVAL, Colombia

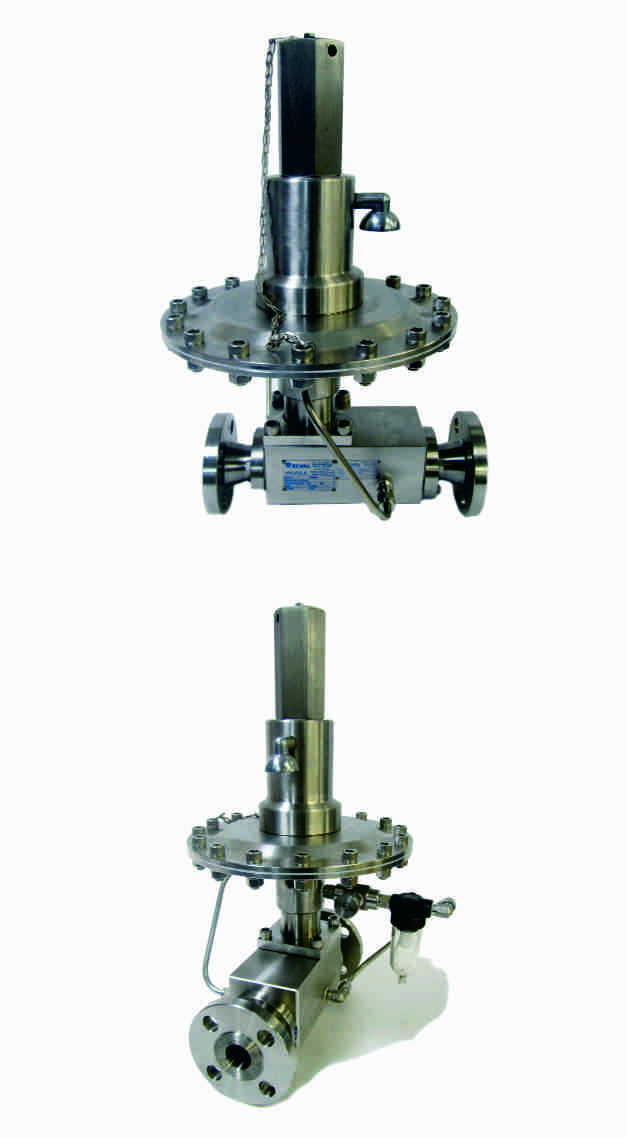

TECVAL blanketing valve reduces pressure and controls gases in low pressure storage tanks (regardless of flow or inlet pressure variations).

Available in carbon steel or stainless steel, self-regulating or pilot operated. Connection sizes from ½” to 3″. Available in flanged (ANSI – DIN) or threaded connections, maximum inlet pressure 200PSI and outlet pressure between 0.5″ H2O and 10PSI. Working temperatures from 32°F to 150°F.

The device is selected according to the required application taking into account the type of fluid, pressure and temperature of the process.

- QUALITY

2 year warranty

Equipment previously tested under conditions similar to its operation (Test Bench). - ENGINEERING

Design and manufacture under specific process requirements.

Design and manufacturing according to application requirements and process conditions.

Selection and sizing by means of specialized software. - TECVAL SERVICE AND SUPPORT

Technical service, under international standards of: calibration, maintenance, repair and testing of devices on site, mobile service centers or in TECVAL service center.

- DESCRIPTION

-

TECVAL blanketing valve reduces pressure and controls gases in low pressure storage tanks (regardless of flow or inlet pressure variations).

Available in carbon steel or stainless steel, self-regulating or pilot operated. Connection sizes from ½” to 3″. Available in flanged (ANSI – DIN) or threaded connections, maximum inlet pressure 200PSI and outlet pressure between 0.5″ H2O and 10PSI. Working temperatures from 32°F to 150°F.

The device is selected according to the required application taking into account the type of fluid, pressure and temperature of the process.

- BENEFITS

-

- QUALITY

2 year warranty

Equipment previously tested under conditions similar to its operation (Test Bench). - ENGINEERING

Design and manufacture under specific process requirements.

Design and manufacturing according to application requirements and process conditions.

Selection and sizing by means of specialized software. - TECVAL SERVICE AND SUPPORT

Technical service, under international standards of: calibration, maintenance, repair and testing of devices on site, mobile service centers or in TECVAL service center.

- QUALITY

REQUEST PRODUCT